Ora ana sing nolak plastik sing duwe peran penting ing pabrik lan kemasan. Nanging, amarga jagad iki tetep nimbang dampak lingkungan global akeh perusahaan sing ngowahi operasi kanggo ngetrapake praktik sustainable.

Kewan minangka pilihan sing paling disenengi kanggo botol plastik (lan panggunaan liyane) amarga 100% daur ulang lan lestari sing lestari. Bisa didaur ulang menyang produk anyar maneh lan nyuda sampah sumber daya. Iki beda karo jinis plastik liyane kayata polyvinyl klorida (PVC), poliethelin sing kurang-densitas (PP), wadhah plastik, wadhah panganan lan cangkir panganan lan cangkir sing bisa digunakake.

Produk Pet bisa duwe siklus umur dawa, gampang didaur ulang, lan daur ulang kewan minangka komoditas sing migunani karo potensial kanggo nutup gelung. Kewan daur ulang bisa digunakake kanggo ngasilake produk pet, kayata: serat loro dimensi, telung dimensi polyester, filamen poliester lan sheet, lsp.

Regulus nyedhiyakake garis produksi daur ulang ing pet profesional. Kita nawakake solusi daur ulang inovatif, sing dirancang khusus kanggo cocog karo ekonomi bunder.

Katrangan Line Procertion Pont:

1 .. Ladang produksi baris produksi kabentuk, otomatisasi gelar, konsumsi energi listrik sing dhuwur, kapasitas dhuwur, efek resik sing apik, dawa nggunakake urip.

2 .. Produk flakes pet Final bisa digunakake kanggo pabrik serat kimia sawise baris iki, lan digunakake kanggo ngasilake tali pet, ora perlu ditindakake.

3. Kapasitas Produk yaiku 500-6000 kg / jam.

4. Ukuran produk akhir bisa diatur miturut ganti bolong layar crusher.

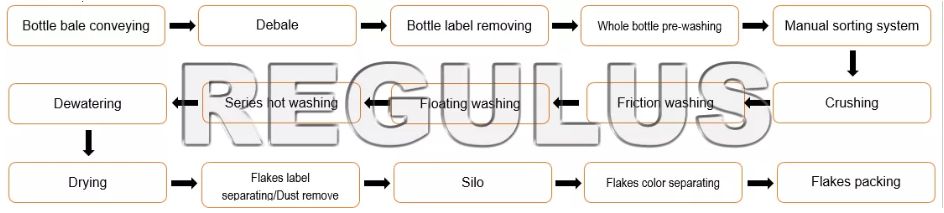

Aliran Produksi Produk Proct:

Sabuk conveyor → Mesin Opening Bale → Mesin Belt → Pre-Washer (Trommel) → Rumput Label Ukuran → Tanduran conveyor → Muncul Conveyor → Muncul Mesin Ukuran → Conveyor ngambang → → mesin cuci ngambang → skru → Mesin deruksi horisontal → sistem pipa pangatusan → sistem klasifikasi pangatusan → sistem klasifikasi pangatusan → stor

Kanggo informasi sing luwih rinci, hubungi kita.

Wektu Pos: Aug-01-2023