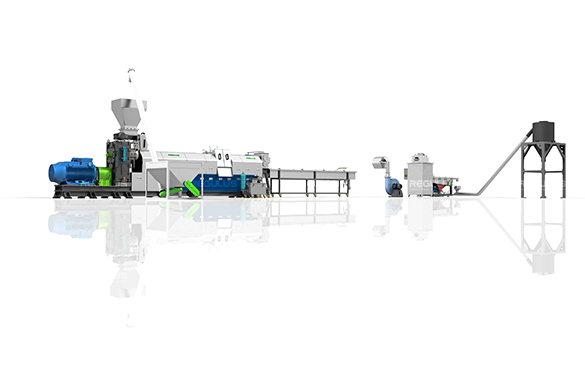

Shredder Shaft Tunggal

Shredder Shaft Tunggal

Cocog kanggo macem-macem bahan. Iki minangka mesin sing cocog kanggo plastik, kertas, serat, karet, limbah organik lan macem-macem bahan. Minangka syarat-syarat pelanggan, kayata ukuran input material, kapasitas lan ukuran output pungkasan lan sapiturute, kita bisa nyambut gawe kanggo klien kita. Sawise diiris ing mesin, bahan output bisa digunakake langsung utawa mlebu ing langkah sabanjure nyuda ukuran. Kanthi fungsi sistem kontrol mikikake Siemens, bisa ngontrol kanthi otomatis Start, mungkasi, sensor mbalikke kanthi otomatis kanggo nglindhungi mesin sing nglawan loading lan jamming.

Aplikasi Produk

| 1. Film plastik / Tong botol / tong plastik / pipa plastik / papan plastik | 2 .. Kertas Kertas / Kertu |

| 3. Plastik Hard: Plastik Plastik / Pungings / Serat / Abs Teknikal Plastik, PC, PPS | 4 .. Kayu / Kayu / Tree Root / Palet Kayu |

| 5. Shell TV / cuci mesin cuci / kulkas: Circuit Boards | 6. Lampu Muncul |

| 7. Sampah Solid: Sampah industri, sampah domestik, sampah medis | 8 .. Kabel |

Produk Akhir

Fitur Produk

| 1 .. Rotor: | Macem-macem konfigurasi rotor kasedhiya kanggo ngolah bahan sing akeh. Bledes digawe saka baja DC53 sing keras; Blading bisa diuripake kaping 4 sadurunge ganti. |

| 2. Gearbox: | Pengawal kothak loled banyu nglawan kakehan. Gigi keras ing suda. |

| 3. Penyerap kejut: | Nyerep geter sing disebabake dening bahan kasebut. Iki nglindhungi mesin lan macem-macem bagean saka karusakan. |

| 4. RAM: | Ram hidraulik nyurung materi saka rotor. |

| 5. Kursi Bearing: | Tutup protèktif kanggo ngindhari kontaminasi manca mlebu omah sing ana. Titik grease kanggo ngeculake minyak ing interval kanggo nambah urip layanan. |

| 6. Layar: | Ukuran layar layar. |

| 7. Stasiun Hydraulic: | Tekanan lan wektu RAM bisa diatur kanggo cocog karo bahan sing beda. |

| 8 .. CE sertifikasi: | Piranti Keamanan Ing sertifikasi CE Eropa |

Paramèter teknis utama

I.wt22 / 40 Seri Tunggal Shaft Shredder:

| Model | WT2260 | Wt4080 | WT40100 | WT40120 | Wt40150 |

| Ruangan CLAM C / D (MM) | 850 * 600 | 1300 * 800 | 1300 * 1000 | 1400 * 1200 | 1400 * 1400 |

| Diameteripun rotor (mm) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Kacepetan Shaft Utama (R / Min) | 83 | 83 | 83 | 83 | 83 |

| Mesh Layar (MM) | φ40 | φ50 | φ60 | φ60 | φ60 |

| Rotor-licives (PCS) | 28 | 40 | 48 | 61 | 78 |

| Daya Motor Utama (KW) | 22 | 37-45 | 45-55 | 75 | 75-90 |

| Power Motor Hydraulic (KW) | 2.2 | 3 | 3 | 5.5 | 7,5 |

II. WT48 Series Shaft Shaft Shutter:

| Model | Wt4080 | WT40100 | WT40120 |

| Ruangan CLAM C / D (MM) | 1300 * 1000 | 1400 * 1200 | 1400 * 1500 |

| Diameteripun rotor (mm) | φ480 | φ480 | φ480 |

| Kacepetan Shaft Utama (R / Min) | 74 | 74 | 74 |

| Mesh Layar (MM) | φ60 | φ60 | φ60 |

| Rotor-licives (PCS) | 48 | 61 | 78 |

| Daya Motor Utama (KW) | 45-55 | 75 | 75-90 |

| Power Motor Hydraulic (KW) | 3 | 5.5 | 7,5 |

III. WTP40 Series Pipa-Single Shredder Shaft Shredder:

| Model | Wtp2260 | Wtp4080 | Wtp40100 | WTP40120 | Wtp40150 |

| Ruangan CLAM C / D (MM) | 600 * 600 | 800 * 800 | 1000 * 1000 | 1200 * 1200 | 1500 * 1500 |

| Diameteripun rotor (mm) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Kacepetan Shaft Utama (R / Min) | 83 | 83 | 83 | 83 | 83 |

| Mesh Layar (MM) | φ40 | φ50 | φ60 | φ60 | φ60 |

| Rotor-licives (PCS) | 28 | 42 | 51 | 63 | 78 |

| Daya Motor Utama (KW) | 22 | 37 | 45 | 55 | 75 |

| Power Motor Hydraulic (KW) | 2.2 | 3 | 3 | 5.5 | 7,5 |

Video kanggo Shredder Pakaian Tunggal:

Tulis pesen sampeyan ing kene lan dikirim menyang kita